Loading...

Be a top competitor in metal fabrication

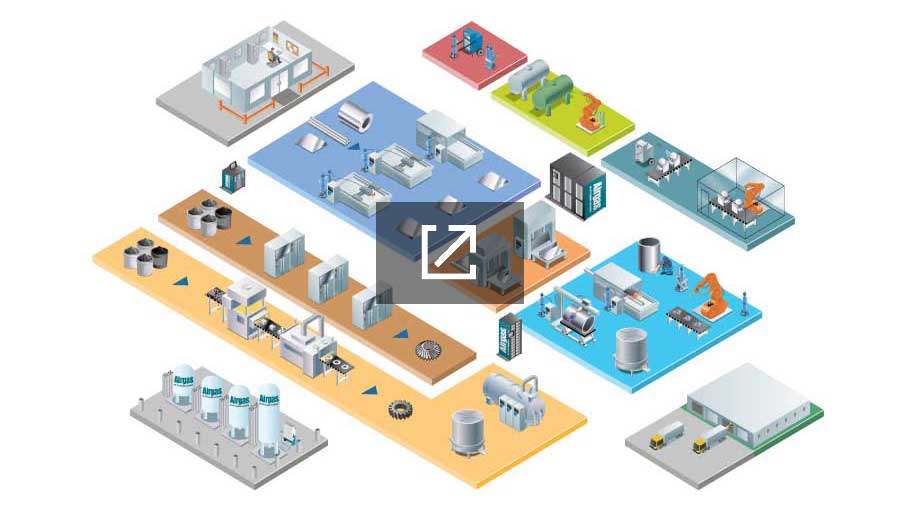

Improve productivity, quality and efficiency with sustainable, cost‑saving solutions from Airgas, an Air Liquide company.

Create value for your metal fabrication operation and your customers

The metal fabrication industry thrives on growth and skill. When the economy is doing well and your labor force is strong, business is good. But how do you sustain that when times get tough or you need to tighten up on spending to prepare for your next big advancement? With an unpredictable market and ever changing business needs, you require dependability and efficiency to stay ahead of your competitors. You need smart solutions, innovative processes and safe procedures to help you meet your goals and deliver value to your customers. No matter what metal you start with, ensure you have everything you need to get a quality product.

What are your challenges?

Unlock expertise and solutions that help you compete in the metal fabrication industry

As one of the industry-leading suppliers to metal fabrication shops nationwide, Airgas has worked with thousands of customers to provide gases, welding and safety products as well as process expertise. Whether it’s helping you fine tune your processes, integrating an automation solution to boost productivity or taking a complete look at your operation through our Unlocking the Hidden Cost of Welding™ program, our priority is finding production efficiencies and cost savings that help you achieve your goals and become more competitive.

We’re also invested in helping you achieve a cleaner, more sustainable operation. We’ve developed cutting, welding, additive manufacturing and heat treatment process solutions that help you reduce emissions. We can also recommend energy efficient processes and lower carbon footprint products to help with your sustainability efforts.

Count on Airgas for unmatched industry advantages

10

Advanced Fabrication

application centers

90+

Advanced Fabrication

experts

2,500+

Customer

case studies

Find out how Airgas serves the metal fabrication industry

Hear from one of our experts

Like many metal fabricators in a highly competitive environment, you need more than just a reliable supplier for all your metal fabrication needs.

Tim Watt, Vice President — Manufacturing & Metal Fabrication

“Like many metal fabricators in a highly competitive environment, you need more than just a reliable supplier for all your metal fabrication needs. As an Airgas customer and with our Advanced Fabrication experts focusing on improvements to your process, you can achieve sustainable cost savings making your business more competitive and profitable.”

Get everything you need to run a productive operation

Access gases nationwide in any supply mode from cylinders to bulk to FLOXAL™ on-site gas generation with local support:

- ARCAL™ shielding gases for welding

- Gases for cutting

Select the right hardgoods based on your equipment and application:

- Consumables and equipment from various manufacturers, including RADNOR™

Implement process solutions that solve your specific challenges backed by the expertise of our team of Advanced Fabrication Technologies experts:

Improve safety for your team and in the communities around you:

- Welding and cutting safety information

- 60+ QSSP- and OSHA 30-certified safety specialists qualified to perform iMSafe™ safety assessments

- Full line of safety products and PPE

- Equipment including regulators, gas detectors and accessories for safe gas handling

Choose the right welding, cutting and automation equipment for your production needs:

- 10 U.S. Advanced Fabrication centers for testing, demos, training and application development

- Equipment installation, set-up and training for welders and equipment operators

- Welder repair and cutting services: retrofitting, service and preventive maintenance

- Used equipment for sale and options to rent, lease or buy welding and weld automation equipment from Red-D-Arc®

Gain visibility, control and savings with supply chain solutions:

- Streamline your procurement process with order management tools

- Improve inventory management with EZ‑VEND® VMI and other vending solutions

- Improve safety and reduce risks with operations management services to help gain efficiencies

- Customize a supply chain solution for your business with Total Managed Services

We can help you even more

Shop our welding collections to get what you need

Resources to keep you ahead

Compete in the Metal Fabrication Industry

Learn more about the tools we offer to help you compete, including systematic savings programs and the expertise of our Advanced Fabrication experts.

Download the Brochure

ARCAL Shielding Gases for Welding

Produce a better quality weld with our premium shielding gases for welding. With five ready-to-weld argon and argon/CO2 mixes plus a Technical line for custom applications, ARCAL covers any welding application.

Download the Brochure

Unlocking the Hidden Cost of Welding

Listen to our customers describe their experience in the Unlocking the Hidden Cost of Welding class and the impact it’s had on the way they see their business.

Watch the Video

When you’re ready, so are we